Platings

High quality metal finishing and coating

Plating services

Cemcoat, Inc. has more than forty years of experience providing high quality metal finishing and coating services including anodizing, etching, chemical filming, passivation, phosphate coatings and zinc electroplating services. Our varied and proven expertise is used to meet the needs of the aerospace, military and commercial industries that we serve. Shown below are specific capabilities for each of the metal plating services we offer.

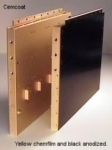

Anodizing

[ MIL – A – 8625F / Type II and III ]

Cemcoat provides clear and colored, soft, hard, and bulk anodizing parts of up to 8.5 feet long. We perform sulfuric acid anodizing in our 8.5′ x 3.5′ x 4′ tank. Our anodizing tank is equipped with automatic amperage control and temperature control systems enabling us to anodize at both fast and slow rates.

Etch

[ MIL – A – 8625F / Type II and III ]

Cemcoat provides ARP-Acid Etch for processing high silicon aluminum castings. We etch to customer specifications and use an alkaline peroxide etching process to create a surface texture ready for adhesive bonding or the application of bonding primers.

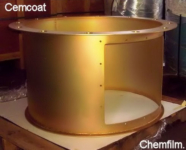

Chemical Film

[ MIL – DTL – 5541F / MIL – C – 5541 ]

Cemcoat provides clear, yellow, and black chemical film as well as cleaning and etching for small and large size aluminum parts in our 8′ x 4′ x 4′ tank. We also provide chemical film with or without hexavalent chromium, and meet RoHS compliance, NADCAP and military specifications.

Passivation

[ QQ – P – 35 ]

Cemcoat provides passivation cleaning film on 300- and 400- series stainless steel parts in our 12′ x 8′ x 4′ tank. The passivation process improves corrosion resistance, provides superior surface cleanliness and eliminates iron contamination reactions with other materials.

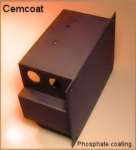

Phosphate coating

[ TT – C – 490 / ASTM – B – 633 ]

Cemcoat provides cleaning processes for ferrous surface, organic coating pretreatments, and zinc phosphate coating. Our largest phosphate plating tank size is 12′ x 8′ x 4′ .

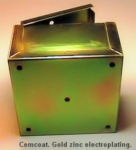

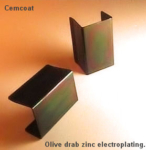

Zinc Electroplating on steel, stainless steel, and aluminum.

[ ASTM – B – 633 / QQZ – 325 / Type I, II, III, and IV ]

Cemcoat specializes in zinc plating of metals up to 15 feet long with blue, clear, gold, black, and olive drab chromate conversion coatings to ASTM – B – 633 standards and RoHS compliance. Our zinc electroplating is non-cyanide alkaline process providing even thickness and is the best for recessed surfaces. We have four zinc processing tanks, the largest being 15′ x 8′ x 4′. This allows us to produce SC1, SC2, SC3, and SC4 thickness grade plating.

For projects that require coatings and complex coatings,

wet spray painting, powder coating or blasting,

Contact Cemcoat today to get started.

Сore values

and our advantages

Industry Experience

With over 40 years of metal finishing experience our leadership team and employees are among the most qualified and committed in the industry.

Attention to detail

Our attention to detail assures that we work diligently to make each customer's experience with us rewarding to meet and exceed expectations.

Approvals

We are currently approved by Teledyne, B/E Aerospace, Marvin Engineering, ITT Corporation, Saint-Gobain, and other small sub contractors.